The Differences Between PEX-A, -B and -C

Developed in 1968 in Europe, PEX pipe came to the U.S. in the mid ‘80s, and for the past 15 years, it has become one of the most common materials used in residential plumbing systems.

When you see PEX-a, PEX-b and PEX-c, you may wonder what the differences are between them and which one you should choose. Below, we break down why there are three kinds of PEX, which traits they share and how they’re different.

How PEX Pipes are Similar

As many of you know, PEX stands for cross-linked polyethylene. The letter that follows simply signifies the type of manufacturing method used to cross link the polyethylene, not the grade of PEX.

If you look in the international plumbing codes, you’ll only see references to PEX, not the different types. That’s because by and large, all PEX pipes are very similar.

They must all meet the same performance standards. There are some requirements that apply to all PEX pipe used for commercial and residential plumbing applications. Others apply to PEX used in specific systems or applications. A few examples include:

- ASTM F876, which is the performance standard for PEX tubing.

- NSF/ANSI/CAN 61 when installed in water distribution systems.

They’re dimensionally the same. PEX size doesn’t change between PEX-a, -b and –c, as defined in ASTM F876. They’re all copper tube size, or CTS.

They all have a material designation code. All PEX pipe is assigned one of these codes based on their level of chlorine resistance, UV resistance and hydrostatic design basis (HDB), or pressure rating.

What are the Differences between PEX types?

The truth is, not a whole lot. Again, the main distinction lies in the manufacturing method, which is what assigns an a, b or c to PEX.

- PEX a is made using the peroxide, or Engel, method.

- PEX b is formed using silane, or moisture cure, method. This is the most common PEX pipe type out there.

- PEX c is created using the electronic irradiation, or cold, method of cross-linking.

There may be small variations in density, burst pressure levels and bend radiuses between PEX pipe types, but they’re negligible. There are, however, a couple of key differences to pay attention to no matter which PEX pipe you’re looking at.

The Material Designation Code

This four-digit number changes depending on the chlorine resistance rating and UV resistance rating as determined in ASTM F876. It can be broken down into three parts:

First digit: Chlorine resistance. The highest rating is Class 5.

Second digit: UV resistance. The highest rating is Class 3, which indicates a six-month UV resistance.

Last two digits: HDB. This is the same for all the PEX tubing sold in the U.S. This will be “06,” indicating a 630 HDB, or a pressure rating of 160 psi at 73 F.

The highest code is PEX 5306.

About SharkBite PEX Pipe

There's no hard-and-fast rule for which PEX pipe — a, b or c — you should use. Given all the similarities and easily identifiable differences, your selection will be based more on your relationship and experience with a particular PEX tubing, your budget and the pipe’s availability in your area.

You can find our USA-made PEX-a and PEX-b pipe at wholesalers, on Amazon, at many home improvement retailers or at your local hardware store.

SharkBite PEX is:

- Approved for use in potable water installations.

- Has the highest chlorine resistance rating (Level 5 for Continuous Recirculation Systems).

- Has the highest UV resistance rating (Level 3 for 6-month UV Resistance).

For more information on SharkBite PEX pipe, check out our detailed catalog.

Read Next: 10 Facts About PEX Pipe You Need to Know

Compatible Systems

Not all fitting systems are approved for use with PEX. To find out which fittings will work best with the tubing brand you choose, check the pipe. Tubing is marked with the standard designations for the fitting systems approved for use with the tubing. All SharkBite PEX tubing, for example, is marked with ASSE 1061, which is the standard for push-to-connect fittings.

Read More: 4 Benefits of Plumbing with SharkBite PEX

Enable Performance and Targeting Cookies to view this content. Update your cookie settings to view this content.

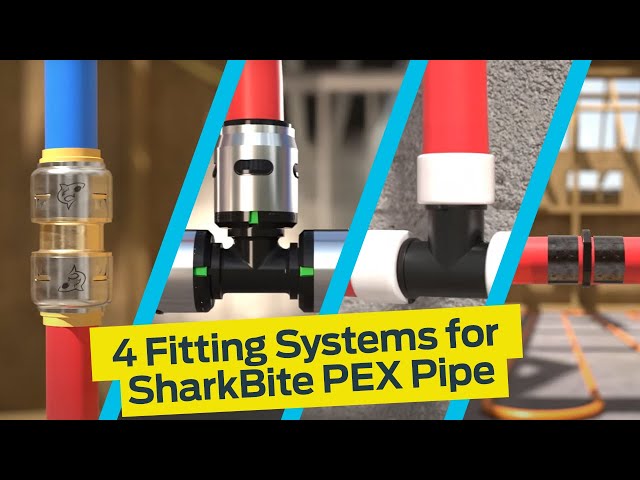

SharkBite offers four reliable fittings systems to use with our PEX pipe. Each system is backed by our 25 year warranty and is manufactured using the highest quality materials, inspections, product testing and assembly. Our owned manufacturing process means we have quality control from raw material to assembly. Read below to find the best system for your application.

1. SharkBite Max push-to-connect fittings

If you need to transition between pipe types, SharkBite Max is the fastest and easiest way to do it. SharkBite Max push fittings make transitions smoother with half the insertion effort and double the burst pressure compared to our first generation of fittings. These fittings are compatible with PEX, copper, CPVC, and HDPE SDR-9 pipe.

2. EvoPEX

For PEX new construction or remodeling applications, choose EvoPEX fittings. They are compatible with PEX-a pipe only and make permanent, secure connections. These push-to-connect fittings include a green indicator that signals a complete connection, which takes the guesswork out of the installation.

3. Expansion

If you need to quickly connect PEX-a pipe but want to keep your options open, use expansion fittings. Since they are available in both brass and polymer, you can choose which material is best for your application— depending on your project needs, budget and preference.

This system is only compatible with PEX-a or PE-RT pipe and is ideal for both residential and commercial plumbing installations.

If you are looking for a durable way to connect any type of PEX pipe, our crimp and clamp system is for you. SharkBite offers both brass and poly crimp fittings, valves, rings and more. They are certified for use in potable water and hydronic heating system applications and depending on your pipe size, water temperature and pressure rating needs, you can choose between brass or poly fittings.

Learn More: 4 Fittings Systems for SharkBite PEX Pipe

Key Takeaways

From commercial to residential and everything in between, SharkBite PEX and PEX fitting systems offer fast, reliable solutions for your plumbing application. Here’s what to keep in mind when choosing a PEX type and fitting system.

Similarities:

- All SharkBite PEX pipe meet ASTM F876 and NSF/ANSI/CAN 61 performance standards and are all copper tube Size (CTS).

- They all have a material designation code based on chlorine resistance, UV rating and hydrostatic design basis (HDB).

- SharkBite PEX-a and PEX-b both have a material designation code of 5306.

PEX-a:

This type is made using the Peroxide, or Engel, method and has the highest-rated flexibility. Expansion fittings are specifically designed for this pipe type, but you can also use SharkBite Max or crimp systems as well.

PEX-b:

This type is formed using silane, or moisture cure, method. It is the most common PEX pipe and is offered in more sizes than PEX-a. It is compatible with SharkBite Max and crimp fittings systems.

PEX-c:

This type is created using the electronic irradiation, or cold, method of cross-linking. It is commonly used for supply lines from the supply stop to the fixture. It may also be used for closed-loop heating systems like radiant floor heating and snow melt systems. SharkBite Max and crimp systems are best suited for this pipe type.